Difference between revisions of "Engine Specs - S65/S85 Rod Bolts"

(→Rod bore distortion) |

(→Which rod bolts are best?) |

||

| Line 3: | Line 3: | ||

== Which rod bolts are best? == | == Which rod bolts are best? == | ||

A lot of people ask which connecting rod bolts are best, and which they should use. There is no simple answer. Factory bolts cost less but take longer to install. Once you use them, you need to throw them away and buy new ones. Aftermarket bolts cost significantly more (3x, 4x) than factory bolts, but they take less time to install and can be reused. | A lot of people ask which connecting rod bolts are best, and which they should use. There is no simple answer. Factory bolts cost less but take longer to install. Once you use them, you need to throw them away and buy new ones. Aftermarket bolts cost significantly more (3x, 4x) than factory bolts, but they take less time to install and can be reused. | ||

| − | + | ||

While there is no doubt aftermarket rod bolts will be higher quality and stronger than factory bolts, they also have some side-effects that most people don't realize. | While there is no doubt aftermarket rod bolts will be higher quality and stronger than factory bolts, they also have some side-effects that most people don't realize. | ||

| − | + | ||

=== Clamping force === | === Clamping force === | ||

Revision as of 22:50, 9 December 2015

Contents

Which rod bolts are best?

A lot of people ask which connecting rod bolts are best, and which they should use. There is no simple answer. Factory bolts cost less but take longer to install. Once you use them, you need to throw them away and buy new ones. Aftermarket bolts cost significantly more (3x, 4x) than factory bolts, but they take less time to install and can be reused.

While there is no doubt aftermarket rod bolts will be higher quality and stronger than factory bolts, they also have some side-effects that most people don't realize.

Clamping force

The ability to keep the rod bore perfectly round will depend on the clamping strength of the rod bolt itself. Believe it or not, all rod bolts when torqued to specifications do not have the same clamping force. To keep the rod bore round will depend on keeping the rod bolts at the same clamping force. You can assume the factory rod bolts when torqued to factory specifications will do the job correctly. But the same can't be said for the aftermarket rod bolts as we shall see below.

Rod bore distortion

The rod bolts play a critical role in keeping the rod big-end bore perfectly round. A properly torqued rod bolt and properly honed rod big-end bore will create a perfectly round circle in the big-end bore. The clamping force is what creates this perfect circle. With improper clamping force, the rod big-end bore will distort, and become out of round.

In theory, whenever the rod bolts are changed, the rod big-end should be re-honed to reestablish the perfect circle of the bore. Re-honing the connecting rod is essential because the clamping force of the new rod bolts will be different. But in reality when people change their rod bearings and install new rod bolts, they can't re-hone the connecting rods because it would require complete engine disassembly. So selecting to correct rod bolt with the correct torque is essential to matching as closely as possible the original factory clamping force. It's not going to be perfect, but it will be good enough.

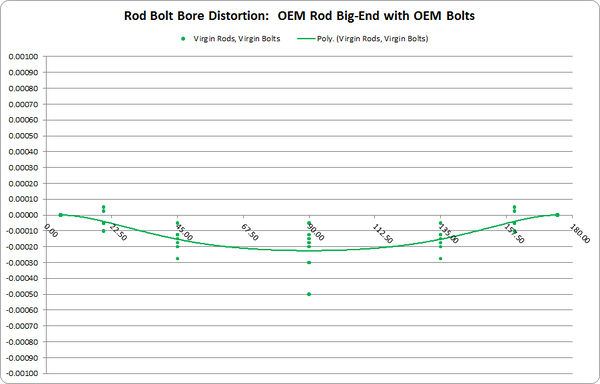

Brand new BMW factory rods have a bit of bore distortion of their own. BMW factory hones the rods with rod bolts at approximately 2/3 of their factory torque specification. When measured in this configuration, the rod big-end bore is as perfectly round as it should be. When you torque the bolts to their proper specification, then a brand new factory connecting rod will have a bit of <negative> bore distortion. After use in an engine, the rods will stretch with the rod bearings and new clamping force; the result is a pretty round bore after new rod bolts are installed.

Here's an example of brand new (virgin) connecting rods with virgin rod bolts. These were honed with rod bolts at 2/3 torque spec. When fully tightened, the virgin connecting rods have the following bore distortion.

Virgin rod with Virgin rod bolts

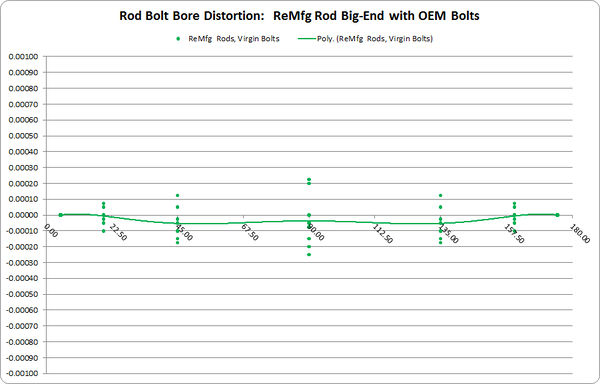

As I mentioned above, lightly used or remanufactured rods have virtually no big-end bore distortion. Here's an example of remanufactured rods that were honed while the rod bolts were correctly tightened. Notice virtually perfectly round bore: no bore distortion.

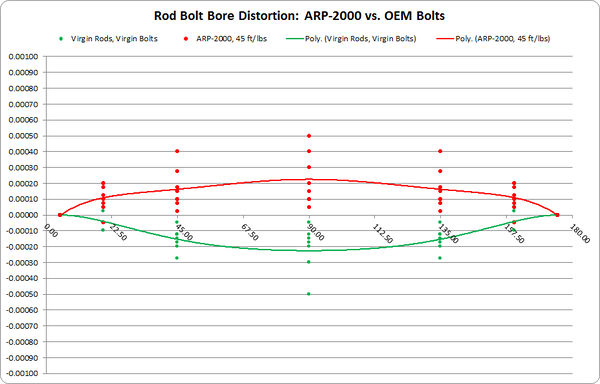

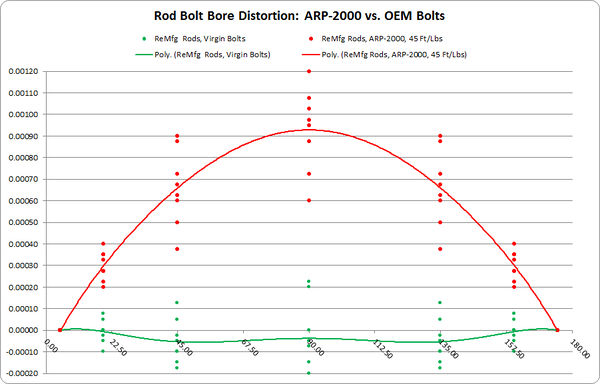

Without the correct clamping force, the rod big-end will distort. This is particularly obvious when aftermarket connecting rod bolts are used. The ARP-2000 and ARP-625 rod bolts are superior quality to OEM connecting rods, but they have a different clamping force than factory rods. Because of this different clamping force, they distort the bore.

Here's an example of an ARP-2000 rod bolt, on a brand new (virgin) connecting rod. This is the same virgin connecting rod shown above. The only difference is the installation of the ARP-2000 connecting rod bolts properly torqued to the manufacture's specification (45 ft/lbs).

ARP-2000 Rod Bolt Bore Distortion

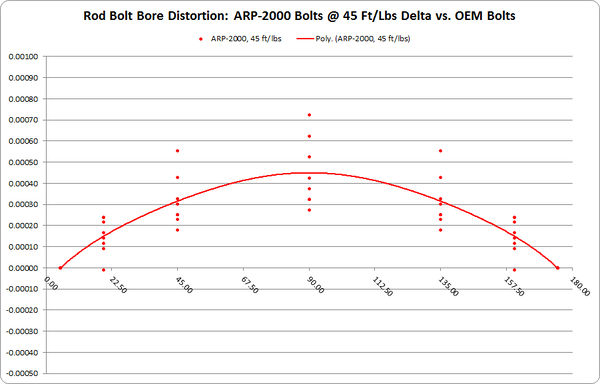

Notice in the graph above there is quite a difference between the factory rod bolts and ARP-2000's. Both rod bolts are torqued to specification, but the shape of the bore hole is vastly different. The following graph will help illustrate only the difference between them. This graph shows the difference between the OEM and ARP-2000 rod bolts. Notice in this graph, there is up to 0.0008 difference at 90-degrees.

Delta: ARP-2000 Rod Bolt Bore Distortion

Factory rod bolts

Specifications: Torque procedure

| Torque | Angle |

|---|---|

| 20 Nm | 130 degrees |

| Remove | |

| 20 Nm | 130 degrees |

| Remove | |

| 20 Nm | 130 degrees |

Make sure you are starting with new rod bolts. Factory rod bolts must be replaced once used.

- Lubricate rod bolt threads and connecting rod cap bore holes with appropriate thread lubricant.

- Torque to 20-Nm, then using a torque-angle gauge tighten another 130-degrees.

- Remove bolts.

- Repeat steps 1-3

- Repeat steps 1, 2.

Specifications: Clamping force

- Approximately 11000 pounds force.

Specifications: Measurements

| Measurement Angle | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 |

|---|---|---|---|---|---|---|---|---|

| 5.00 | 2.20495 | 2.20500 | 2.20510 | 2.20510 | 2.20500 | 2.20510 | 2.20495 | 2.20500 |

| 19.75 | 2.20500 | 2.20490 | 2.20500 | 2.20510 | 2.20500 | 2.20510 | 2.20480 | 2.20500 |

| 45.00 | 2.20500 | 2.20480 | 2.20500 | 2.20495 | 2.20500 | 2.20490 | 2.20480 | 2.20490 |

| 90.00 | 2.20520 | 2.20480 | 2.20500 | 2.20480 | 2.20520 | 2.20490 | 2.20480 | 2.20500 |

| 135.00 | 2.20520 | 2.20490 | 2.20500 | 2.20480 | 2.20510 | 2.20500 | 2.20490 | 2.20490 |

| 160.25 | 2.20510 | 2.20490 | 2.20500 | 2.20500 | 2.20510 | 2.20500 | 2.20490 | 2.20500 |

| 175.00 | 2.20500 | 2.20500 | 2.20500 | 2.20500 | 2.20500 | 2.20500 | 2.20480 | 2.20500 |

Specifications: Rod bore distortion

| Measurement Angle | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 |

|---|---|---|---|---|---|---|---|---|

| 5.00 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 |

| 19.75 | 0.00007 | -0.00010 | -0.00005 | 0.00000 | 0.00005 | 0.00000 | -0.00003 | 0.00000 |

| 45.00 | 0.00012 | -0.00015 | -0.00005 | -0.00017 | 0.00005 | -0.00010 | -0.00003 | -0.00010 |

| 90.00 | 0.00022 | -0.00020 | -0.00005 | -0.00025 | 0.00020 | -0.00015 | -0.00008 | 0.00000 |

| 135.00 | 0.00012 | -0.00015 | -0.00005 | -0.00017 | 0.00005 | -0.00010 | -0.00003 | -0.00010 |

| 160.25 | 0.00007 | -0.00010 | -0.00005 | 0.00000 | 0.00005 | 0.00000 | -0.00003 | 0.00000 |

| 175.00 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 |

ARP-2000 rod bolts

ARP-2000 rod bolts are a step up in strength and quality from OEM factory bolts. These bolts for S65/S85 are custom made by ARP for VAC Motorsports. ARP does not manufacture and sell these bolts to the public. You can only get these through VAC Motorports.

Specifications: Torque Procedure

- 45 ft-lbs.

- Unlike the factory rod bolts, these may be reused.

Specifications: Clamping force

- TBD

Specifications: Measurements

| Measurement Angle | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 |

|---|---|---|---|---|---|---|---|---|

| 5.00 | 2.20480 | 2.20480 | 2.20480 | 2.20475 | 2.20480 | 2.20475 | 2.20475 | 2.20485 |

| 19.75 | 2.20510 | 2.20500 | 2.20510 | 2.20510 | 2.20520 | 2.20515 | 2.20515 | 2.20500 |

| 45.00 | 2.20560 | 2.20515 | 2.20540 | 2.20560 | 2.20540 | 2.20545 | 2.20545 | 2.20530 |

| 90.00 | 2.20600 | 2.20540 | 2.20565 | 2.20580 | 2.20575 | 2.20575 | 2.20580 | 2.20560 |

| 135.00 | 2.20580 | 2.20520 | 2.20540 | 2.20560 | 2.20540 | 2.20545 | 2.20555 | 2.20545 |

| 160.25 | 2.20520 | 2.20500 | 2.20500 | 2.20500 | 2.20495 | 2.20510 | 2.20520 | 2.20520 |

| 175.00 | 2.20480 | 2.20480 | 2.20475 | 2.20470 | 2.20480 | 2.20480 | 2.20480 | 2.20490 |

Specifications: Rod bore distortion

| Measurement Angle | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 |

|---|---|---|---|---|---|---|---|---|

| 5.00 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 |

| 19.75 | 0.00035 | 0.00020 | 0.00027 | 0.00033 | 0.00027 | 0.00035 | 0.00040 | 0.00022 |

| 45.00 | 0.00090 | 0.00038 | 0.00062 | 0.00088 | 0.00060 | 0.00067 | 0.00072 | 0.00050 |

| 90.00 | 0.00120 | 0.00060 | 0.00087 | 0.00108 | 0.00095 | 0.00097 | 0.00102 | 0.00073 |

| 135.00 | 0.00090 | 0.00038 | 0.00062 | 0.00088 | 0.00060 | 0.00067 | 0.00072 | 0.00050 |

| 160.25 | 0.00035 | 0.00020 | 0.00027 | 0.00033 | 0.00027 | 0.00035 | 0.00040 | 0.00022 |

| 175.00 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 0.00000 |

ARP-2000 Rod Bolt Bore Distortion

ARP-2000 Rod Bolt Bore Distortion

ARP-625 rod bolts

Specifications: Torque Procedure

- TBD

- Unlike the factory rod bolts, these may be reused.

Specifications: Clamping force

- TBD

Specifications: Measurements

TBD

Specifications: Rod bore distortion

TBD

Carrillo WMC rod bolts

Specifications: Torque Procedure

- TBD

- Unlike the factory rod bolts, these may be reused.

Specifications: Clamping force

- 8150 Pounds pressure

Specifications: Measurements

TBD

Specifications: Rod bore distortion

TBD

Carrillo M9-CARR rod bolts

Specifications: Torque Procedure

- TBD

- Unlike the factory rod bolts, these may be reused.

Specifications: Clamping force

- TBD

Specifications: Measurements

TBD

Specifications: Rod bore distortion

TBD